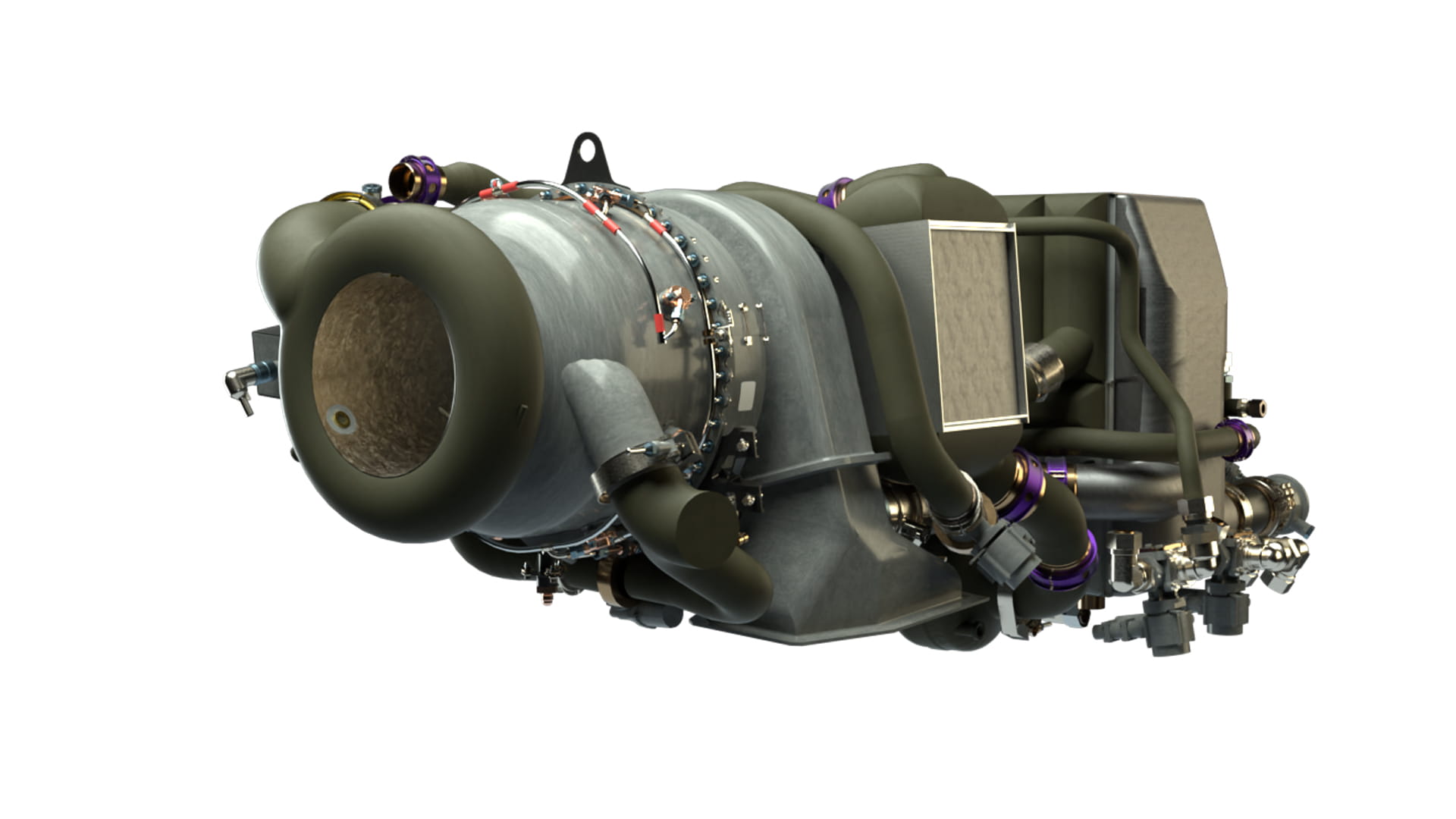

For more than 70 years, Collins Aerospace has led the industry by pioneering new and advanced power and thermal management system (PTMS) capabilities. Extensive experience in the PTMS space allows us to offer the Enhanced Power and Cooling System (EPACS) for the future of the F-35 platform.

EPACS offers twice the cooling capacity and reduced engine bleed air usage, so pilots won’t have to think twice about the performance capabilities of their aircraft. EPACS would enable F-35 Block 4 modernization and beyond, unlocking the performance potential of current and future fleets.

Powerful performance & enhanced capability

Capable

Collins Aerospace has solved this problem of increased cooling demand time and time again. As a leading provider of thermal management systems, electric power generation and distribution, and auxiliary power units, we are experts on all the key subsystem functions of EPACS. By integrating these capabilities, we are applying proven solutions to support modernization of the F-35.

The Boeing 787 is just one example that combines environmental control systems, electric power generation and distribution, and the auxiliary power unit. Collins designed, integrated and delivered these systems to reduce engine bleed air usage and optimize the energy usage aboard the aircraft. These systems have over 10 million cumulative flight hours and counting.

Low risk

EPACS uses proven, demonstrated technologies, and we’ve executed hardware prototype testing to further burn down risk. Many of the enabling technologies applied to EPACS have been fielded on multiple military and commercial systems to provide maximum cooling capacity while minimizing bleed air penalty. This allows EPACS to maximize cooling as well as increase range and thrust all while providing additional system durability benefits.

Ready

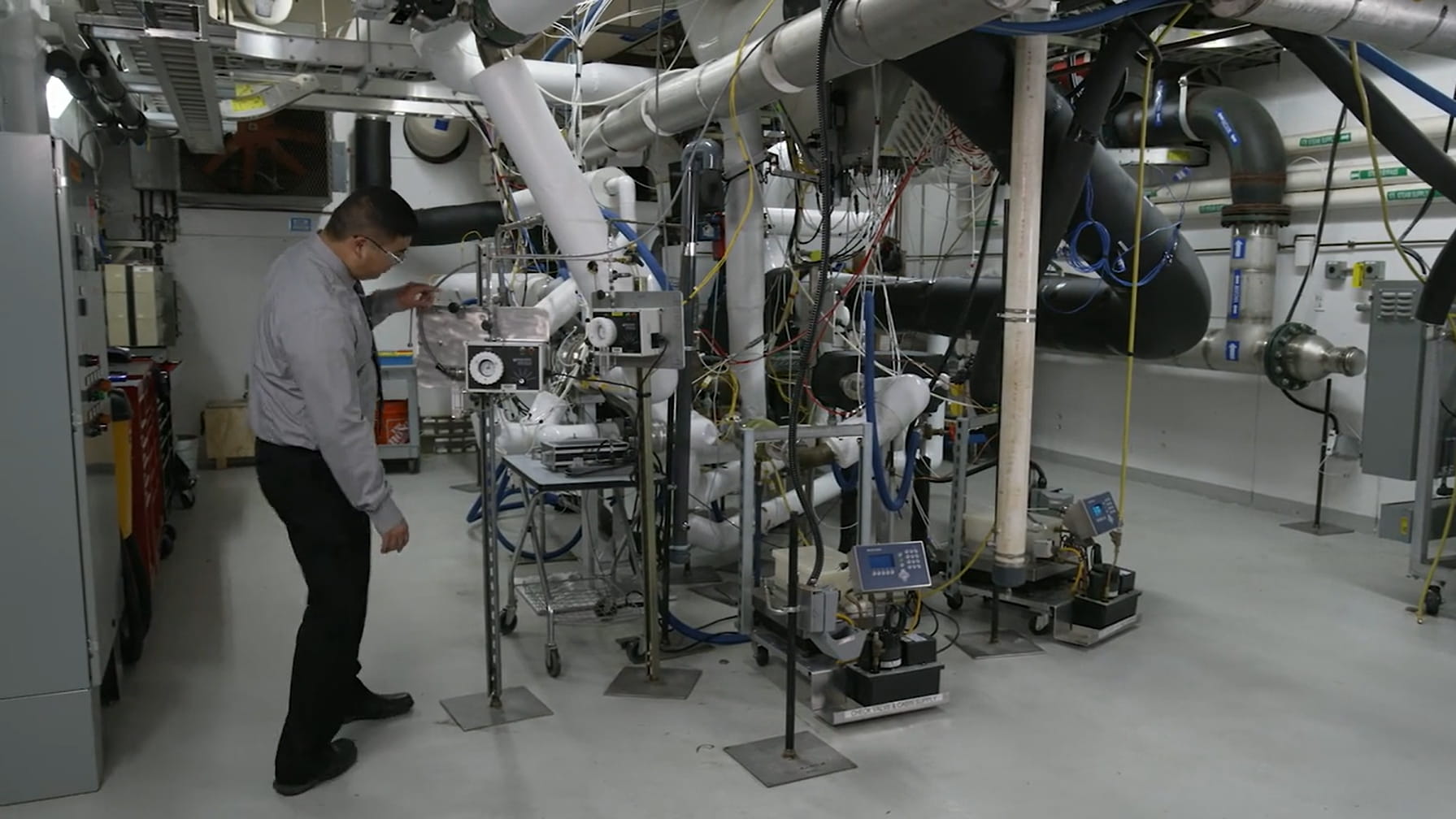

With a successful lab demonstration on the books, EPACS remains poised to meet the cooling needs for tomorrow’s F-35. We have invested millions of dollars into our state-of-the-art thermal systems development labs which allows Collins to simulate relevant real-world conditions on a fighter, including a wide range of temperatures, pressures, air flow rates and humidity conditions. Our system and component labs have always been future-forward and equipped to evaluate new solutions in the power and thermal management space for both commercial and defense applications.

Along with a large and capable manufacturing footprint that is already delivering components for the F-35 today, we are ready to meet the production, cooling and volume constraints of this thermal challenge.